SKF and Sieb & Meyer Announce Strategic Partnership for Magnetic Bearing Solutions

SKF has entered into a strategic partnership with Sieb & Meyer, a renowned specialist in variable frequency drives (VFDs) and control electronics. The collaboration marks an important milestone in delivering integrated, high-efficiency inverter solutions tailored for demanding applications such as air compressors, turbochargers, and HVAC systems.

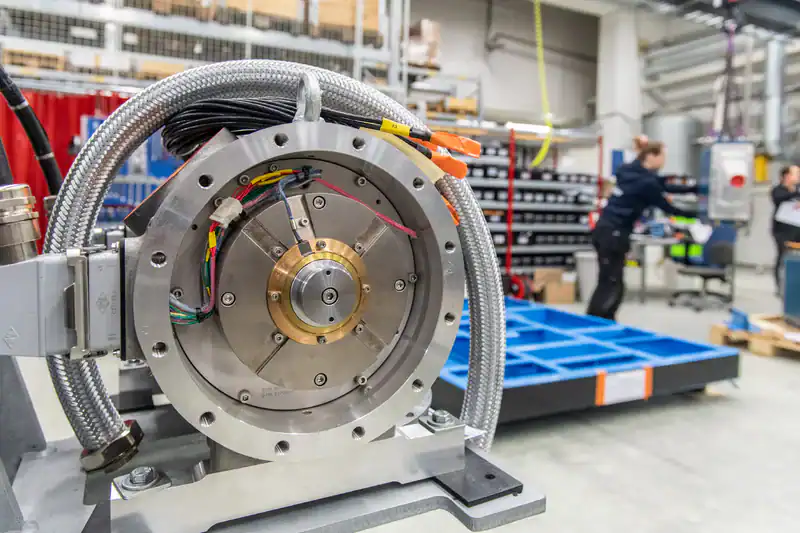

As part of the agreement, SKF will manufacture VFDs at its own facilities, leveraging Sieb & Meyer’s expertise in high-speed inverter technology. The result will be a seamless plug-and-play solution that simplifies integration, reduces engineering time, enhances system reliability, and ensures scalability for future applications.

The partnership will significantly strengthen SKF’s offering by combining its high-speed electric motors with magnetic bearings and precisely tuned VFDs for optimized performance, energy efficiency, and durability.

“By combining our expertise in magnetic mechatronics with Sieb & Meyer’s VFD technology, we are setting a new standard for high-speed motor systems. This partnership enables us to provide customers with a more complete and efficient solution,” said Frederic Ponson, Director of SKF Magnetic Mechatronics.

“This collaboration is a powerful alignment of expertise. By integrating Sieb & Meyer’s advanced inverter technology with SKF’s high-speed motor systems, we’re delivering a smarter, more efficient solution that meets the evolving demands of HVAC, air compressors, and blower applications. Together, we are establishing a new benchmark in performance and reliability,” added Markus Meyer, CEO of Sieb & Meyer.

Looking ahead, the partnership plans to expand into additional sectors, including boil-off gas compressors and spindle drive systems, broadening the industries that can benefit from this integrated approach.

SKF also emphasized the sustainability benefits of magnetic bearing systems, which eliminate oil-related pollution and reduce energy consumption compared with conventional bearing solutions. In energy-intensive applications such as wastewater treatment, compressed air, and HVAC, high-speed electric motors with magnetic bearings can cut energy use by up to 30%. This translates into overall savings of 10–15% across facilities while helping to lower greenhouse gas emissions from electricity generation.

Moving The Sea With Us!

Contact us today: +351 265 544 370 or go to Contacts Page

Email: sales@partyard.eu

#PartYard #MovingTheSeaWithUs #SKF #SiebAndMeyer #Partnership #MagneticBearings #VFD #HighSpeedMotors #Innovation #Sustainability #EnergyEfficiency #HVAC #AirCompressors #Turbochargers #CleanEnergy #GreenTech #EngineeringExcellence #FutureTechnology #SmartSolutions #IndustrialInnovation